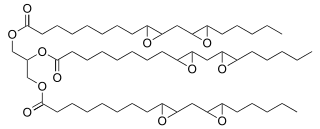

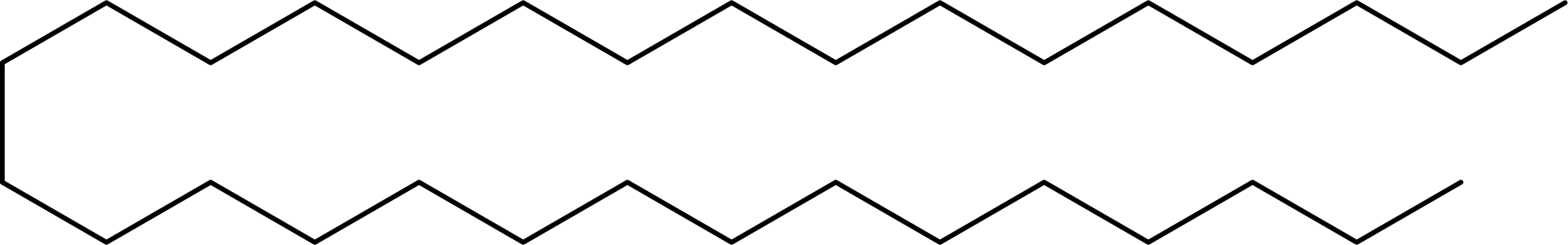

Calcium stearate (CS) and Zinc stearate (ZS) are Metallic stearates. Metallic stearates are lubricants used in multiple plastic and rubber applications. They act as lubricants and acid scavengers during the manufacturing process. It is also used as a co-stabilizer in PVC. Their high melting point enables faster, easier and smooth processing in various industries.

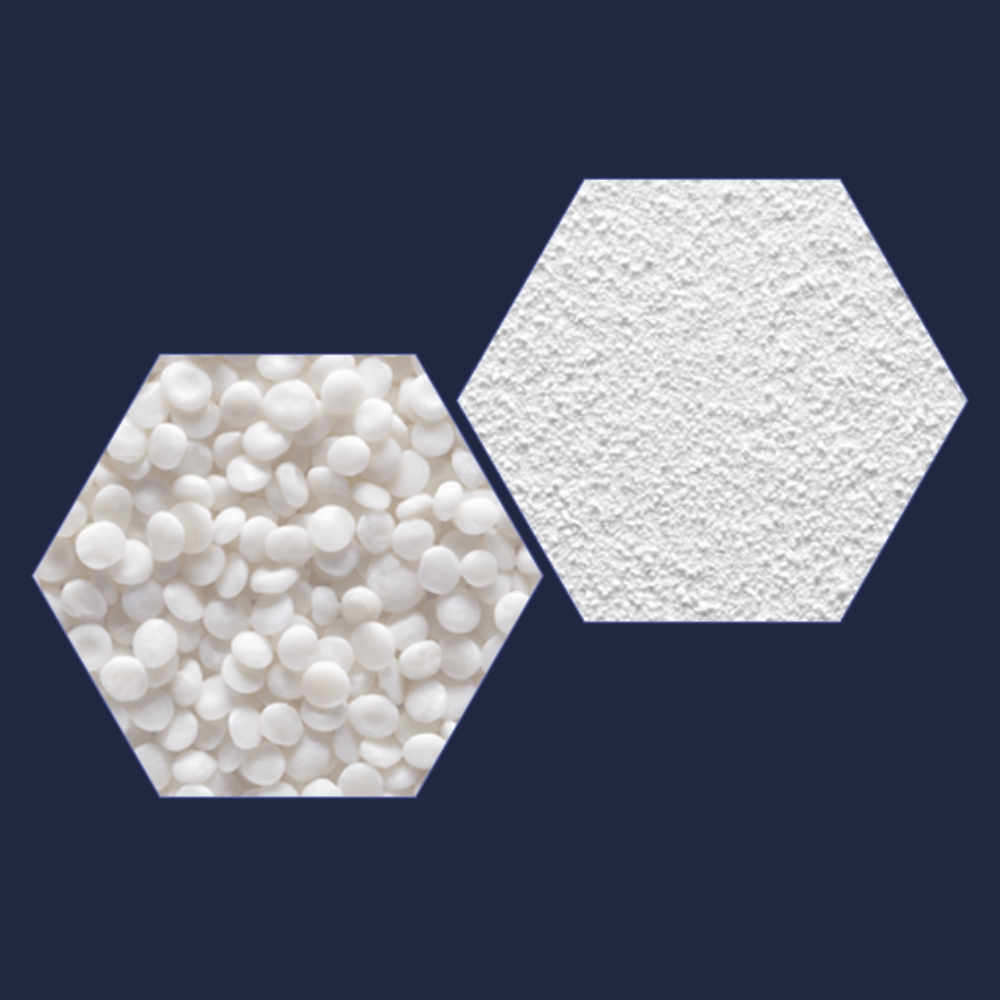

Product Available at SNG Microns Private Limited

| Calcium stearate (CS) | Zinc stearate (ZS) |

Calcium stearate (CS)

Calcium stearate (CS)

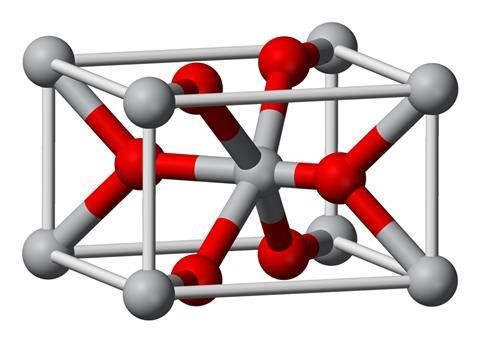

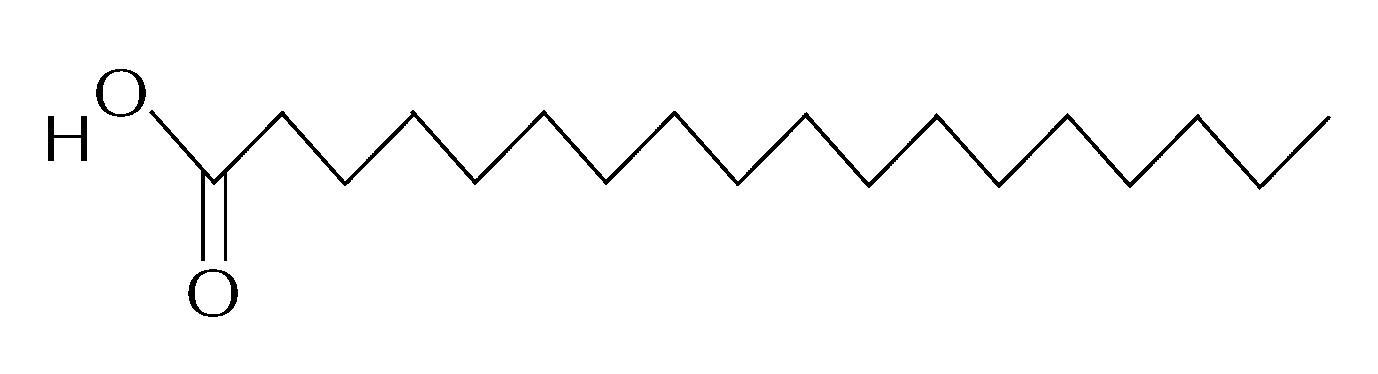

Calcium stearate (Chemical Name: Octadecanoic Acid Calcium Salt) is a carboxylate of calcium, classified as a calcium soap. It is a component of some lubricants, surfactants, as well as many others. It is a white waxy powder.

Calcium stearate is an odourless, white powder used in many manufacturing processes and preparations. It is a carboxylate created by heating stearic acid and calcium oxide.

Typical usages of Calcium stearate

| Industry | Typical Usages |

| Plastics | Internal and External Lubricant in PVC Rigid Extrusion, Polyethylene Chain Length Modifier and a De-Dusting Agent |

| Rubber | Release Aid, Adhesion Prevention |

| Food, Pharma and Nutraceuticals | Mold Release for Tableting, Stabilizer, Emulsifier, Source of Calcium, Excipient, Anti-Tack Agent |

| Cosmetics | Anti-Caking Agent in Powdered Cosmetics |

| Lubricants and Greases | Thickening Agent |

| Personal Care | Anti-Tack and Gelling Agent |

Calcium stearate has many potential uses, including as a flow agent, stabilizing agent and surface conditioner in the production of certain foods — notably, many candies. It is used as a mold-release agent for pharmaceutical tablets and capsules, as an anti-caking agent in cosmetics and as a thickener in lubricants and greases. It is also a stabilizer found in many plastics and is used to process concrete and paper.

Calcium stearate is harmless, and is insoluble in most solvents. Compared to waxes, it has a comparatively high softening point, and, consequently, do not become greasy at higher temperatures. Calcium stearate is primarily used as lubricant in the plastics industry, an acid scavenger, release agent and, for waterproofing in construction, and as an anti-caking additive in pharmaceuticals and cosmetics.

Typical Property of Calcium stearate (CS)

| Parameters | Specifications | |

| Appearance | White Powder | |

| Calcium Content | % | 6.8 – 7.4 |

| Calcium Oxide (CaO) | % | 9.0 – 10.5 |

| Moisture Content | Max % | 3.0 |

| Heavy Metals, ppm | Max | 10 |

| Ash Content | % | 9.0 – 10.0 |

| Free Fatty Acids | Max % | 1 |

| Mean Particle Size Micron | Typical | 10-12 |

| Bulk Density (G/Cc) | Typical | 0.18 |

| Melting Point | °C | 148 – 160 |

| C16 | 0 – 56 | |

| C18 | 40 – 100 |

Zinc stearate (ZS)

Zinc Stearate is an oleochemical substance featuring a white, powdery appearance. Zinc Stearate has the ability to resist water and is insoluble in certain types of polar solvents. Zinc Stearate is formed by combining stearic acid with zinc oxide, the latter of which is an organic white-powder compound that is insoluble in water. While it does not produce a strong odour, Zinc Stearate powder does have a slight fatty acid scent.

There are many methods to manufacture Zinc Stearate. In addition to the direct method of combining stearic acid with zinc oxide, there is also an indirect method known as precipitation, which entails the formation of a solid from a liquid solution. The fusion method involves a high-shear process using tightly controlled pressure and temperature conditions.

Zinc Stearate offers a number of chemical properties that are invaluable from a manufacturing perspective.

Key benefits of Zinc stearate (ZS)

| Lubricity | Compatibility |

| “Sharp” melting point | Hydrophobicity |

The above-mentioned key benefits differentiate Zinc Stearate from other metallic stearate materials.

Typical usages of Zinc stearate (ZS)

| Industry | Typical Usages |

| Plastics | Zinc Stearate (ZS) is a highly effective pigment dispersion aid and lubricant in PVC, polyethylene and ABS production. Zinc Stearate also acts as a scavenger for acidic residues in polyolefin manufacture and is used as a mold release agent and process lubricant in the production of polystyrene.

|

| Rubber | Zinc Stearate serves as an internal lubricant in molded rubber production and as an external lubricant or dusting agent with excellent anti-block properties. Zinc Stearate (ZS) uses in rubber manufacturing is as a release agent, as well as an activator for rubber vulcanization |

| Paint and coatings | improves the abrasiveness of sandpapers and matting agent |

| Construction | Hydrophobic agents for plasters |

| Cosmetic | Zinc Stearate (ZS) acts as an anti-caking agent in powdered cosmetics. Other uses of Zinc Stearate in cosmetics include as a lubricant, as well as a thickening agent for enhancing texture |

Typical Property of Zinc stearate (ZS)

| Parameters | Specifications | |

| Zinc Content | % | 10.6 – 11.25 |

| Total Ash (as ZnO) | % | 12.75 – 14.50 |

| Moisture | Max % | 0.5 |

| Free Fatty Acid | Max % | 1.5 |

| Soluble Salts | % | Nil |

| Melting Point | ºC | 117 – 125 |

Why to buy from SNG Microns Private Limited

We at SNG Microns offers Calcium Stearate (CS) and Zinc Stearate (ZS) for various industrial applications. As one of the leading distributors of oleochemicals in the eastern India with more than 25 years of experience, you can count on us for superior Zinc Stearate and Calcium Stearate products at competitive prices.