Products

Impact Modifier

Most rigid and semi rigid PVC compounds have impact performance requirements that can be met only through the use of impact modifiers. Generally, in order to improve the impact resistance of PVC products, impact modifiers (toughening agents) are being used. For the superior IMPACT we supply CPE 135A and ELASTOPACK

CPE acts as a coupling agent between fillers and PVC particles. This allows high filler loading without sacrificing physical or optical properties.

Product available at SNG Microns Private Limited

| CPE | Elastopack (AIM) | MBS |

Type of Impact Modifiers

| Chlorinated polyethylene (CPE) | Acrylic Processing (AIM) | Methacrylate(M), Butadiene(B) and Styrene(S) (MBS) |

| Typical applications are:

PVC pipe, footwear, etc |

Typical applications are:

pipes, window profiles, sidings, furniture sheets. |

Typical applications are: sheets, food-packaging film, bottles, blister packs, pipes and fittings. |

Chlorinated polyethylene

Chlorinated polyethylene (CPE or PE-C) is a low-cost alternative of polyethylene, where chlorine is substituted for some of the hydrogen atoms. CPE has a chlorine content generally from 34% to 44%. Chlorinated polyethylene can be crosslinked peroxidic ally to form an elastomer which is used in Plastic, cable and rubber industries. CPE is impact improver with high molecular weight, good mechanical performance and impact improver for rigid plastic products.

Typical Properties of Chlorinated polyethylene

It has fine multiple physical property with good low-temperature flexibility and better tearing strength. Its dissolved parameter is nearly same as PVC and it has good affinity with PVC. Under the condition of right processing, it can form a network composition inside of the hard PVC finish products and give them good normal, low-temperature flexibility and impact strength.

| Parameters | Unit | CPE135A |

| Chlorine content | % | 35+/-1 |

| Thermal Decomposition Temperature | oC | >=165 |

| Bulk Density | g/ml | >=0.5 |

| Volatile Content | % | <=0.4 |

| Particle Size (36 mesh) | % | 99 |

| Impurity Particle | PC/50g | <=10 |

| Shore Hardness | A | <=65 |

| Tensile Strength | MPa | >=6.0 |

Acrylic Impact Modifiers

Acrylic Impact Modifier is a Weatherable Impact Modifier used in rigid PVC products. It is a “core -shell” structure modifier, with cross-linked poly butyl acrylic as “core” and graft methyl methacrylate as “shell”. It not only improves impact resistance performance of the product, but also increases the surface gloss of the product, and especially the weatherability of the product. It is especially suitable for outdoor products and broadly used in PVC profiles, sheets, boards, pipes, pipe fittings, etc.

Acrylic polymers with a core-shell structure used as Impact Modifiers in PVC formulations for outdoor applications. Impact Modifiers are suitable for the use in PVC applications where a good balance of impact strength and gloss, as well as excellent weatherability, is required.

MBS

MBS products developed with advanced synthetic resin technology, ternary copolymerized by Methyl Methacrylate (M), Butadiene (B) and Styrene (S). It is an integrated resin for improving impact strength and processing performance of PVC products. Generally, Manufacturers offers MBS impact modifier range is tailor-made for the specific needs for rigid and semi-rigid indoor PVC applications, whether the requirement is extreme impact resistance or guaranteed high transparency.

MBS, core is made of butadiene or butadiene styrene having Tg (-) 70 ° C. The shell is made up of PMMA. Due to butadiene core, it is not preferred for outdoor application.

Key benefits of MBS

| Good impact strength | Good gloss | Excellent weatherability |

Applications of Impact Modifiers

For U-PVC pipes in India, if fusion is optimized, addition of impact modifiers is not necessary for pipes not exposed to severe weather conditions. However, for profiles having sharp corners and window profiles exposed to solar radiation, impact modifier is necessary.

Impact modifiers are used for long term use of PVC/C-PVC products especially under cold conditions and outdoor exposure. C-PVC pipes used for conveying hot water from solar heaters or geysers are usually exposed to solar radiation and weathering. Therefore, impact modifiers shall be judiciously selected for C-PVC pipes for indoor and outdoor use.

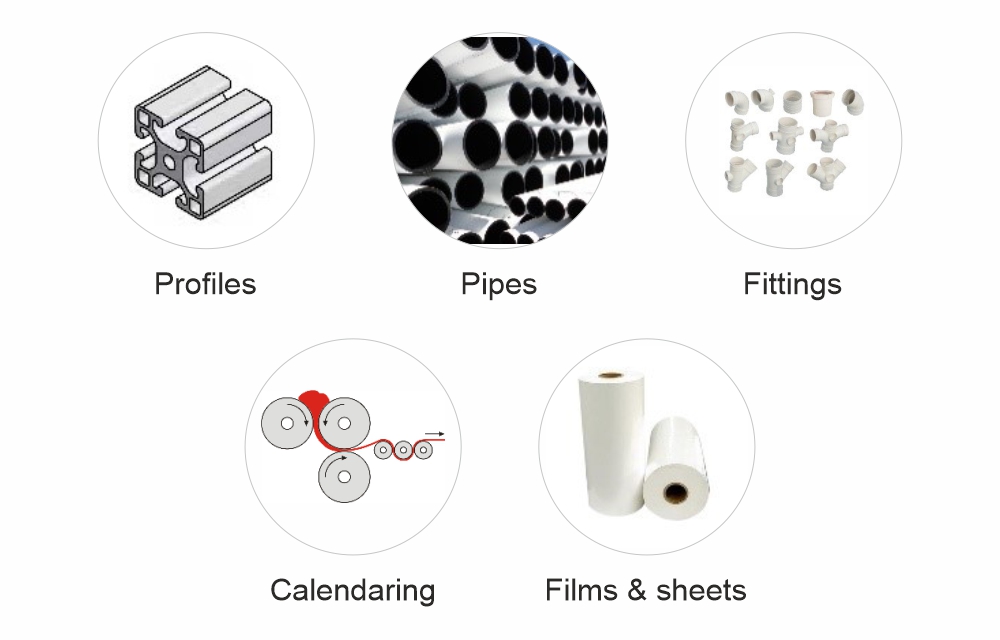

Impact Modifiers are recommended for being used in PVC formulations for a wide range of applications such as:

Comparison between Chlorinated polyethylene (CPE) and Acrylic Impact Modifiers (AIM)

Comparison of AIM and CPE on 1 to 5 scale (5 being Best)

| Parameters | CPE | AIM |

| Strength | 4 | 4 |

| Rigidity | 3 | 4 |

| Thermal stability | 4 | 5 |

| Weatherability | 4 | 5 |

| Processability | 3 | 5 |

| Tg (glass transition) | CPE (-) 16 ° C | core (-) 45 – (-) 60 ° C, shell 70-120 ° C |

Key Market Players of Impact Modifiers

| Manufacturers Name | Country |

| Dow Inc. | USA |

| Lanxess A.G. | Germany |

| Kaneka Corporation | Japan |

| Arkema S.A. | France |

| Mitsubishi Chemical Corporation | Japan |

| LG Chem Ltd. | South Korea |

| Shandong Ruifeng Chemical Co., Ltd | China |

| Mitsui Chemicals, Inc. | Japan |

| Wacker Chemie AG | Germany |

| Formosa Plastics Corp. | Taiwan |

| Sundow Polymers Co., Ltd | China |

| SI Group, Inc. | USA |

| Akdeniz Kimya San. ve Tic. Inc. | Turkey |

| En-Door | China |

| Novista Group | China |

| Indofil Industries Limited | India |

* List not exhaustive

Why to buy impact modifiers from SNG Microns Private Limited

We sell the original quality impact modifier, you may be aware that there is calcium contain in CPE impact modifier, hence the result of different brand of CPE varies based on ingredient used in manufacturing of CPE. The higher filler (Calcium Carbonate) contents in CPE gives sub-optimal results. We at SNG understand your requirements and suggest the best possible impact modifier Applicable for your applications. We get the testing of our imported impact modifier and get assured about the quality of products before offerings to customers.