Products

Wax

Waxes are a diverse class of organic compounds that are lipophilic, malleable solids near ambient temperatures. They include higher alkanes and lipids, typically with melting points above about 40 °C, melting to give low viscosity liquids. Waxes are insoluble in water but soluble in organic, nonpolar solvents. Natural waxes of different types are produced by plants and animals and occur in petroleum.

Type of Waxes used in PVC Plastic (Pipe & fittings); available at SNG Microns Private Limited

|

Polyethylene wax

|

Paraffin Wax

|

Hydrocarbon Wax

|

Polyethylene wax (PE Wax)

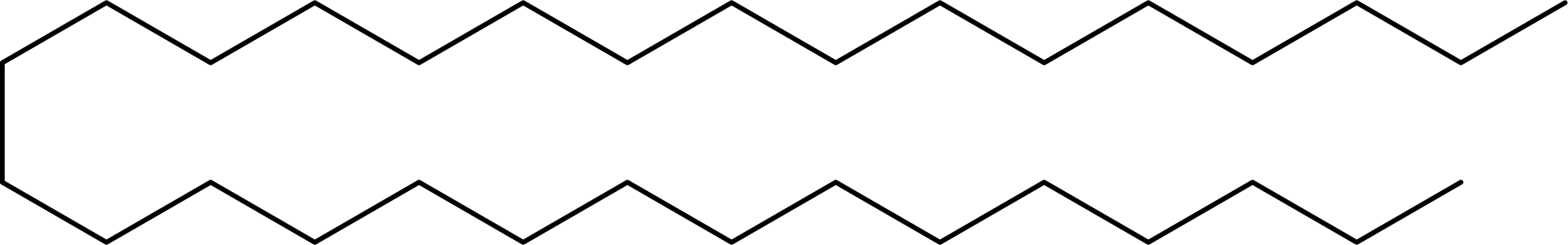

PE WAX is polyethylene homopolymer wax; an ultra-low molecular weight polyethylene consisting of ethylene monomer chains, an excellent and consistent ingredient for end formulations to improve product physical appearance and thermal properties for a broad range of industries, including hot melt adhesives, PVC, colour masterbatches, rubber and thermoplastics road markings, etc

PE wax is derived from ethylene through a process called polymerization. Manufacturers alter the polymerization process to get a product with desired qualities. However, certain basic properties of the material are common for all PE wax. polyethylene wax is linear and crystalline. That is why this material finds applications such as blends, plastic additives and rubber manufacture

PE wax is heat-stable, lowly soluble, chemically resistant and hard. Combining these features with abrasion resistance and broad melting points makes the material the undisputable choice for a wide range of industrial applications

Paraffin Wax

Paraffin wax is mostly found as a white, odourless, tasteless, waxy solid, with a typical melting point between about 46 and 68 °C. Paraffin wax was first created in 1830 by the German chemist Karl von Reichenbach when he tried to develop the means to efficiently separate and refine the waxy substances naturally occurring in petroleum.

Paraffin wax which was first produced commercially in 1867, within 10 years after the first petroleum well was drilled. Paraffin wax precipitates readily from petroleum on chilling. Technical progress has served only to make the separations and filtration more efficient and economical. Purification methods consist of chemical treatment, decolorization by adsorbents, and fractionation of the separated waxes into grades by distillation, recrystallization, or both. Crude oils differ widely in wax content.

Hydrocarbon wax (HC wax)

Hydrocarbon wax (HC wax) is an excellent external lubricant for PVC Processing. PVC has natural tendency of sticking to metal at the time of processing and hence it is not lubricated externally and as such the extrusion results are not satisfactory.

By using HC Wax as a Lubricant, one will achieve higher rate of production, shining smooth internal and external surface.

Application of Wax

Wax has many physical and chemical properties that make it suitable for a wide range of industrial applications. Like PVC pipes -fitting, CPVC pipe-fitting, uPVC pipes-fittings, PVC clothing, PVC furniture, PVC flooring, PVC door-window, PVC footwear, PVC blister film, PVC rigid sheet, PVC flexible film, PVC packaging film, PVC lamination film, PVC stretch film, PVC shrink film, PVC celuka foam board/sheet, WPC sheet, WPC profiles/chokhat, PVC free foam sheet, advertising flex banner, PVC suction-garden tube, PVC rigid/flexible profiles, automotive products and many other application like Masterbatch, textile finishing, cosmetics, polishes, paper coating, leather auxiliaries, adhesives, carriers for pigment concentrates, and in paints and printing ink industry. Plastic, Candles, Packaging, Coatings & Polishing, Hot Melt Adhesive, Tire & Rubber, Cosmetics & Personal Care, Food, Others.

Top 10 manufacturers of waxes across globe

| ExxonMobil (US) | Hollyfrontier Corporation (US) |

| Royal Dutch Shell PLC (Netherlands) | Calumet Specialty Products Partners (US) |

| Sinopec (China) | Gandhar Oil refinery (India) |

| Sasol Ltd (South Africa) | Numaligarh Refinery Limited (India) |

| CEPSA (Spain) | Petróleo Brasileiro (Brazil) |

| THE PJSC Lukoil Oil Company (Russia) |

Indian wax manufactures are

Numaligarh Refinery Limited (NRL), Indian oil, Gandhar Oil Refinery (India) Limited and few others.

Why to buy wax from SNG Microns Private Limited

We not only directly source the materials from Indian manufactures but also import from world largest manufactures. There are many unrefined or semi-refined waxes in the market sold by various traders which have more oil contents or hardness. Our wax colour is super white. When you touch it with your hands, give you feel of good smoothness. It feels like plastic rather than wax. It is hard, brittle, fragile, and does not form a mass at room temperature. Paraffin; containing high impurity or oil are greasy, greasy to the touch, feel like touching candles, soft and sticky. If you hold them with your hands, they will form a ball. The genuine product smells like plastic, while breaking the flake of PE Wax, it gives crack sound while inferior quality just soften while breaking or break with low sound.