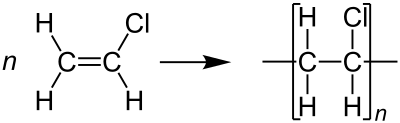

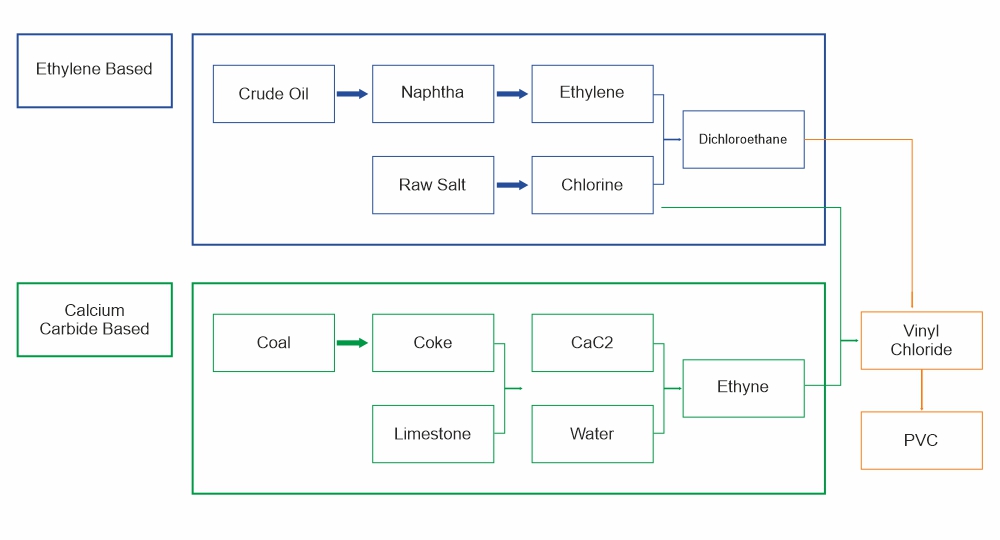

A One Pack Stabilizer is a pack of additives added during the processing of PVC. The additives are a combination of various chemicals. The PVC molecule is unstable to heat and light hence to process PVC, it has to be stabilised against the action of Heat required at processing temperatures. That is the reason for using One Pack Stabilizer. This One Pack has helped manufactures to just use one chemical rather than using multiple chemicals like DBLS, TBLS, LS etc traditionally being used. One Pack Stabilizers play important roles during processing as well as during the service life of the product to which they are added.

One Pack Stabilizer available at SNG Microns Private Limited

| S. No. | Type | Form |

| 1 | Leads | Flex, Powder |

| 2 | Ca – Zn | Powder |

| 3 | Tins | Liquid |

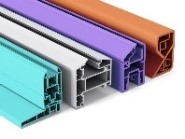

Form of One Pack Stabilizers

| Lubricated | Non-Lubricated |

Non-Lubricated One Pack Stabilizers are high performance stabilizers that are specially designed for optimum performance in PVC Pipe and fittings. It come in form of Flex or Powder.

Type of One Pack Stabilizers

|

Toxic

|

Non-Toxic

|

| Lead Based | Calcium, Zinc, Barium, Tins, Metallic Stearates, etc. |

Lead Based One Pack Stabilizers

Lead Based One Pack Stabilizers that are metal complexes together with Stearates and Lubricants that are produced in solid form and most popular among PVC Pipe and Fittings manufactures. It has major advantages like high heat resistance and low cost.

Non-Toxic One Pack Stabilizers

Non-Toxic One Pack Stabilizers are based on Calcium, Zinc, and Barium or other chemicals that are blended with co-stabilizers and lubricants to make the product heavy metal free. However, currently available Non-Toxic One Pack Stabilizer in market has moderate heat resistance because of this the dosages are added compare to lead based stabilizer hence cost become higher for manufactures of PVC Pipe and fittings.

How to choose One pack stabilizer

The correct choice of stabilisers for the target application is best done in consultation with the stabilizer supplier and technical experts, However, as a general guideline the below given table may be useful.

PVC One pack stabilizer application areas

| Type | Heat Stability | Main Applications | Not recommended for |

|---|---|---|---|

| Leads | Very Good | Cables, Pipes & Fittings, Sleeves, Profiles | Clear Application. Can be toxic. Cheapest. |

| Tins | Best | Transparent tubings and sheeting, High quality Pipes, Medical industry | Causes sulphide staining with Leads. Costliest Stabiliser. |

| Cd – Zn | Moderate | ROHS Cables, Non-Toxic. Pipes and Extrusions | For high heat history |

| Ca – Zn | Moderate | ROHS Cables, Non-Toxic. Pipes and Extrusions | For high heat history |

| Ba- Cd | Good | Leather Cloth, Calendared products, Footwear | Non-Toxic applications |

| Cd – Zn | Moderate | Foamed Leather Cloth | For high heat history |

| Metallic Stearates | Low | Co-stabilisers with lubricating action | Sole stabilizer |

Newer families of heat Stabilisers are being researched, developed and offered with the background of environments contamination concerns. Organic Stabilisers and Calcium Zincs are in the forefront of this trend and leading the way. We already sell non-toxic one pack stabilizers.

Lead stabilisers: Because of its relatively lower cost and strong Stabilisation action, Lead stabilisers have historically been the most popular, however from 1st April 2022, lead base stabilizer is banned / restricted in many PVC Pipe and other plastic application by Government of India. Lead stabilisers consist of TBLS, DBLS, LS and few other additives.

How does the produced quality is different in PVC Pipe but Lead percentage (%) is same of different one pack stabilizer?

The one pack stabilizer is made of various chemicals and minerals, like Calcium Carbonate, Stearic Acid, Lead etc, just lead percentage does not signify quality of products, even lead is of better and worst quality, same with calcium carbonate, stearic acid and other ingredients. Hence quality of one pack stabilizer depend of raw materials being used in manufacturing of one pack stabilizer not just lead percentage.

Calcium- Zinc One Packs stabilizer

With the India moving away from Lead stabilizer along with world to control environments contamination and health. Calcium- Zinc based One pack stabilizer are becoming prominent for manufacturing Lead Free Pipes and where ROHS requirements are to be met as per BIS (Bureau of Indian Standards).

The lubrication systems in Ca-Zn are quite complex for boosting the efficiency, so many of the Calcium- Zinc grades are available as one packs and not individual components at present in market in India unlike lead based one pack stabilizer where DBLS, TBLS, LS are available individually.

Calcium- Zinc Stabilizers mainly consist of Calcium Stearate, Zinc Stearate, organic and inorganic non-toxic co-stabilizers, and internal and external lubricant.

Our Calcium Zinc stabilizers provide initial colour sufficient for PVC processing and our stabilizers are used to give excellent whiteness and long-term stability.

Calcium Stearate (CS)

Calcium Stearate (CS) is the most common non-Lead stabiliser. However, its stabilising power is quite low and is more viewed as a very effective Internal Lubricant, playing a major role in Lubrication at the die head for smooth extrusion and finish. Hence currently CS is not being used as stabilizer rather it is being used for smoother the extrusion and other benefits.

One Packs stabilisers – Tins

The other major stabilizer system is with Tins, very popular in the Americas, as they were very effective with single screw extruders, which was the norm there before the Americas also switched over to Twin screw. Tins One Packs stabilisers mostly being used in CPVC Pipes & Fittings, PVC Pipes & Fittings, PVC Films (Calendaring Film, Shrink Film, Rigid Film, Short Film), PVC Leather Cloth, PVC Hose Pipes, PVC Garden Pipes, PVC Windows & Door Profiles, Medical Tubing, Blister Tray (Food Grade), PVC Toys among others.

Top Global manufactures of One Packs stabilizer

| Baerlocher GmbH | Arkema SA |

| Adeka Corporation | Songwon Industrial Company Limited |

| Galata Chemicals | Pau Tai Industrial Corporation |

| Reagens SPA | Akzonobel N.V. |

| BASF SE | Clariant AG |

| Addivant USA, LLC. | Akcros Chemicals Ltd |

Major Market Players in Eastern India of One Packs stabilizer

Goldstab Organic, Baerlocher, Pondy oxide & chemicals, Faith Industries, Balasore Chemicals, MLA group, Shital industries among others.

Distribution System or buying or availability of One Packs stabilisers

In India, generally all the manufactures have appointed their authorised distributor for every state / region. Hence for buying One Packs stabilisers of particular brand, customers need to approach the designated distributor. All distributors have different terms and conditions. The quality of One Packs stabilizer varies among players as the one who invest most on R&D are able to produce best One Packs stabilizer.

Why to buy from SNG Microns Private Limited

We offer an extensive portfolio of one pack of PVC heat stabilizers for a wide range of applications like Pipes, Profiles, Fittings and other industries with an emphasis on high-performance. Our Calcium-Zinc stabilizers are performance-oriented and particularly provide excellent long-term retention of colour, outstanding mechanical properties and a high level of the weathering resistance. We are one of authorized distributor of the of the most leading manufactures of India.